Real-world scenarios need to be taken into account when designing HMI. There should be no unnecessary functions that can potentially cause safety issues like they did for […]

Blog

Integrate Milk Standardization Into Your Control System

Milk standardization systems have traditionally been stand-alone systems provided by original equipment manufacturers (OEMs). Currently, many of these installed systems contain components which are obsolete or have […]

Minimizing Fat Loss in the Dairy Process

In 2015, an average U.S. dairy fluid milk plant processed 109.5 million pounds of milk. On average that same plant encountered an average product loss of 2.5%. […]

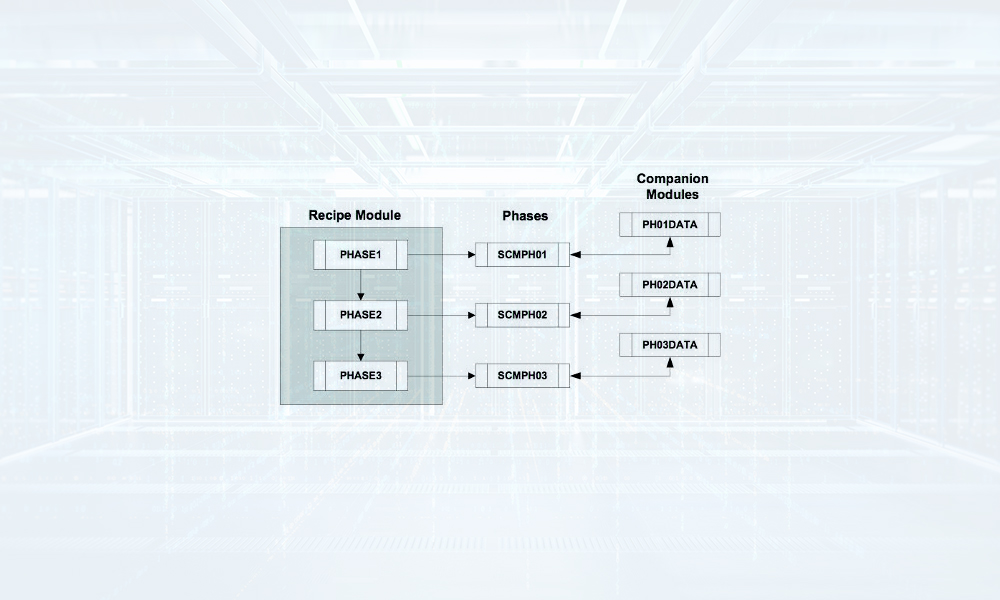

Three Tips to Make the Coding Process Easier

Sequential control programs can be easier and more streamlined if the engineer ensures that the sequences have the same architectural model. Three tips are highlighted to […]